Why are preliminary tests needed?

The University of Strathclyde and QinetiQ teams executed a number of tests and activities to qualify the space hardware of the Particle Vibration (T-PAOLA) experiment, the involved materials (including the fluid and particles required for the experiment itself) and optimise several procedures. Such activities are summarised below in terms of aims, procedures and related execution.

Visualisation tests

The aims

The purpose of the test was to ensure that particles can be clearly seen using the optical modules (interferometers) of the Selectable Optical Diagnostics Instrument (SODI).

The procedure

- Particles were inserted in a cell partially filled with water. Then vibrations were applied to visualise particles temporarily being suspended in the liquid as a results of the shaking effect.

- Particles were encapsulated in a transparent resin matrix mimicking the conditions established in space (particles apparently “floating” into an external transparent medium).

The execution

QinetiQ and the science team executed these tests during summer 2019 at QinetiQ Belgium. Such tests demonstrated that particles having a size of 100 microns could be clearly visualised.

Heavy particles in vibrated cell partially filled with distilled water

Light and Heavy particles in a transparent medium

Short duration compatibility tests

The aims

The purpose of the test was to provide a preliminary evaluation of the compatibility of candidate elastomeric seal materials (used to seal the fluid containers) with the experimental fluids and inform the down-seleciton of seal material to be used for the ensuing long-term compatibility test.

The procedure

Test cells were sealed with membranes made of different materials. The behaviour of these mebranes was monitored for several weeks.

The execution

QinetiQ executed these tests during autumn 2019 at QinetiQ UK. The compatibility of three candidate elastomeric seal materials with the

experimental fluids was assessed. Results showed that only one cell passed all the test success criteria. The related membrane was therefore selected as a baseline component to manufacture the cell arrays.

Submerged compatibility tests

The aims

The cells used to host the fluid-particle mixtures envisaged by the Particle Vibration project are made of two main components: Quartz and two metal plates. The objective of the Submerged Compatibility Test was to confirm compatibility of the experimental fluids with these materials or parts.

The procedure

The execution

QinetiQ executed these tests during the autumn 2019 at QinetiQ UK. No visual changes to the sample materials submerged in ethanol resulted from the 12 months submerged compatibility test. The mass of the samples after the test changed by less than 5%.

Long duration compatibility tests

The aims

The purpose of this test was to qualify the containers to be used for the particle Vibration experiment using the fluids and particles selected by the science team, to assure that there is no long-term incompatibility between them and the materials from which the real configuration needs to be tested.

The procedure

Science team and QinetiQ had to:

- Scale the particles

- Insert them in the cell

- Mount the filling setup on the cell

- Vacuumise the cells

- Fill the cells

- Remove apparent bubbles

- Close the cell with the membrane

The execution

These tests ran from 11th of December 2019 till 11th of June 2020. The tests of heavy and light particles with ethanol did not show any compatibility related anomalies and therefore were considered to have been completed successfully.

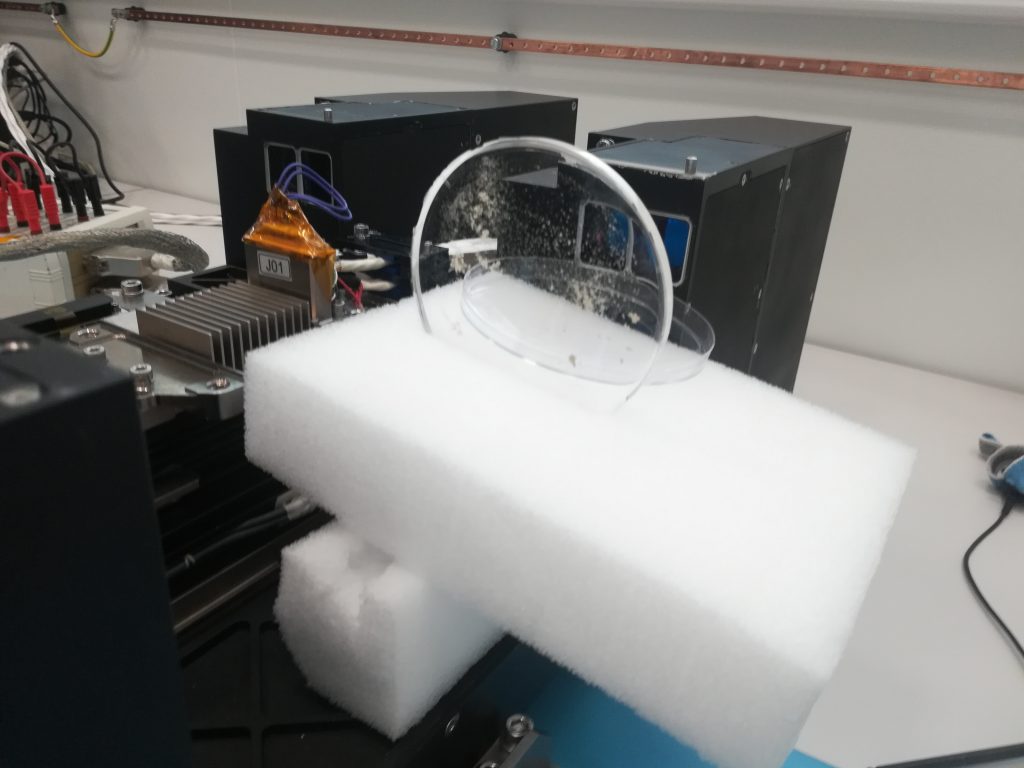

Cell Array Vibration Tests

The ground activities have not been limited to materials compatibility verification. Given the delicate nature of some of the particles (especially the hollow glass ones, see the liquid and particle preparation page), additional investigations have been conducted to assess the risk of particle breakage during acceptance testing of the flight hardware and/or due to the spectrum of vibrations produced during launch with the SpaceX rocket:

Low Frequency (0 – 100Hz)

- Excitations driven by global vehicle motion and modes

- sine vibration envelope this region

- Mid Frequency (100Hz – 600Hz)

- Excitation due to aero acoustics

- Acoustic excitation and aero buffet are primary drivers in this region

- High Frequency (600Hz – 2000Hz)

- Excitation due to structure borne vibration

- Merlin Vacuum (MVac) forcing functions

Accordingly, sine sweep resonance research testing with acceleration level fixed to 0.5 g and vast frequency range (5-2000Hz) and random vibration testing have been implemented.

This series of tests have been conducted using a cell array containing two ethanol-filled cells, one with heavy and one with light particles). This cell array was packed in its stowage bag, as it would be before flight, and encapsulated into a rigid box (the ‘vibration jig’).

The verification has been conducted by applying random vibrations along all the axes of the reference system

The final state of the particles has been assessed through comparative analysis of photographs of the cells before and after testing for each axis of vibration; moreover, since broken particle fragments sink, the amount of breakage has been quantitatively substantiated through visual inspection of the sedimented phase. Overall, launch vibrations have not been found to damage particles.

The interested reader will find additional details about all these activities in “Particle Vibration, an instrument to study particle accumulation structures on board the International Space Station“, Microgravity Science & Technology (ISSN: 0938-0108), 34(3), article number 33 (24 pages), 2022.